Precision engineering is revolutionizing how industries approach material design, quality assurance, and product innovation. In sectors like healthcare, aerospace, and automotive manufacturing, stainless steel plays a defining role in ensuring consistency and reliability. As technology evolves, industries are adopting advanced alloys that meet both performance and environmental standards.

The rise in automation, smart manufacturing, and data integration has significantly boosted the Precision Stainless Steel Market worldwide. The demand for precise, corrosion-resistant, and durable materials is driving manufacturers to develop custom alloys tailored for specific applications. Whether used in robotic arms, surgical equipment, or micro-machined components, precision stainless steel ensures high accuracy under extreme conditions.

An important dimension of this industry involves sustainability. Companies are optimizing production through low-emission furnaces, energy recycling systems, and improved raw material utilization. These practices not only reduce environmental impact but also cut operational costs, reinforcing the long-term value of stainless steel innovation.

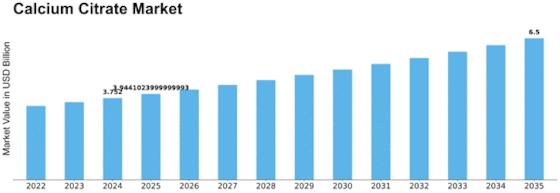

According to recent Calcium Citrate Demand trends, the global precision materials industry is shifting toward eco-efficient manufacturing to align with circular economy goals. Recycled steel and closed-loop systems have become integral to sustainable industrial frameworks, offering both economic and environmental benefits.

The ongoing advancements in metallurgical science continue to open new pathways for the precision stainless steel industry. With expanding applications in renewable energy and precision medicine, the market’s future is not just strong—it’s sustainable and smart.